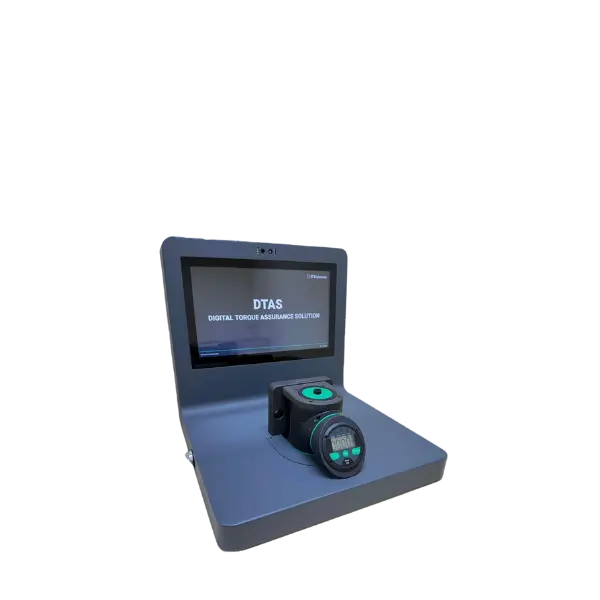

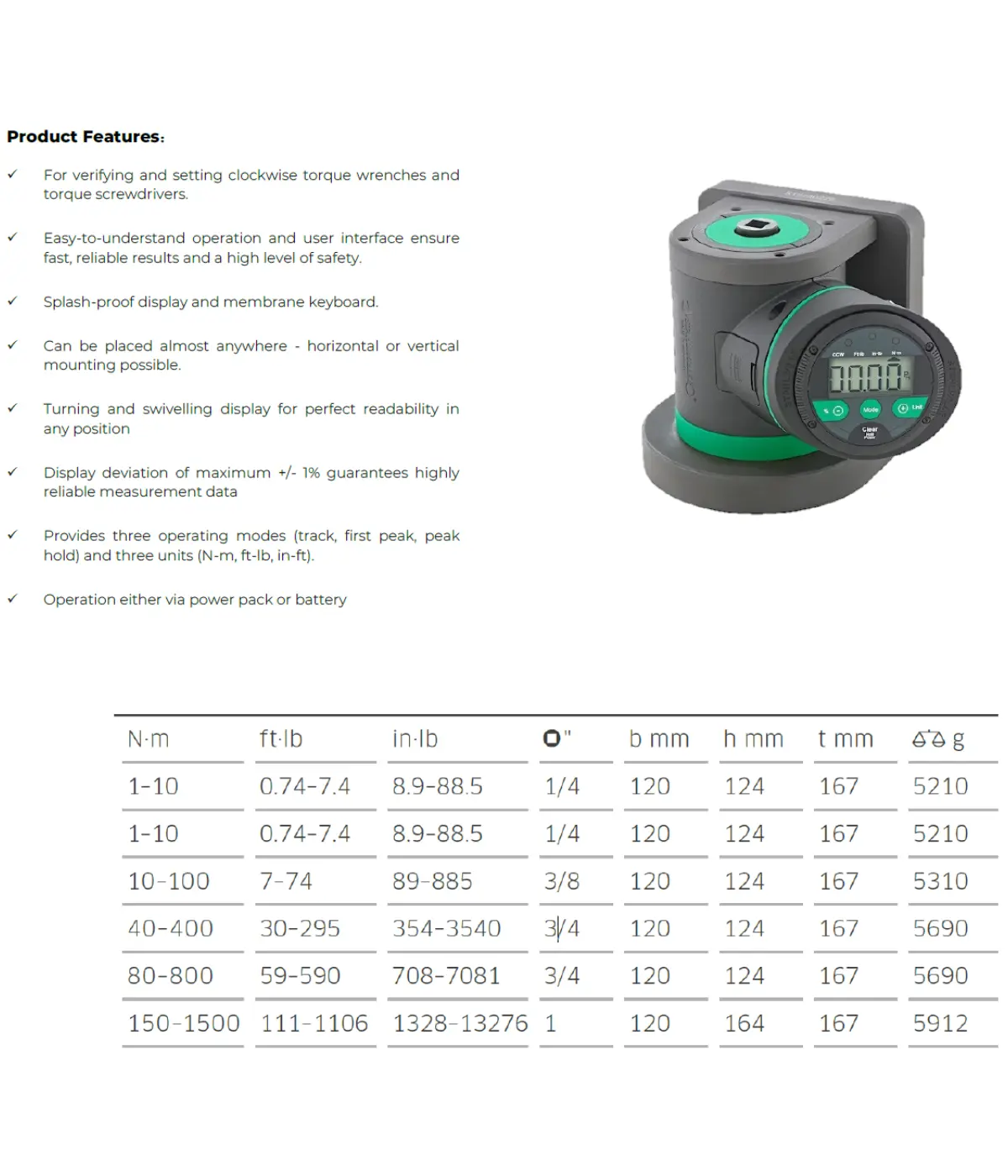

Digital Torque Assurance Solutions (DTAS)

The Digital Torque Assurance Solution (DTAS) allows users to test torque tools before and after use, ensuring they remain within tolerance.

Regular checks backed with system data can potentially extend calibration cycles, reducing downtime and operational disruptions.

DTAS provides a proactive approach to maintaining tool accuracy and operational efficiency.

Maintenance, Repair and Operations (MRO)

Specializes in maintaining and repairing aircraft and vehicles for optimal performance and safety.

Electrical Power Generation & Transmission

Concerned with the production of electricity in power plants and its distribution to consumers through extensive transmission networks.

Factories & Production Facilities

Encompasses facilities where goods are manufactured or processed, incorporating a variety of production methods and technologies.

Health & Medical

Dedicated to patient care and medical research, this industry focuses on effectively managing healthcare facilities and medical supplies.

Prisons & Detention Facilities

Facilities designed for the confinement and rehabilitation of individuals charged with or convicted of crimes, focusing on security and containment.

Defence & Military

Pertains to national defense and security services, including the development, production, and maintenance of military equipment and operations.